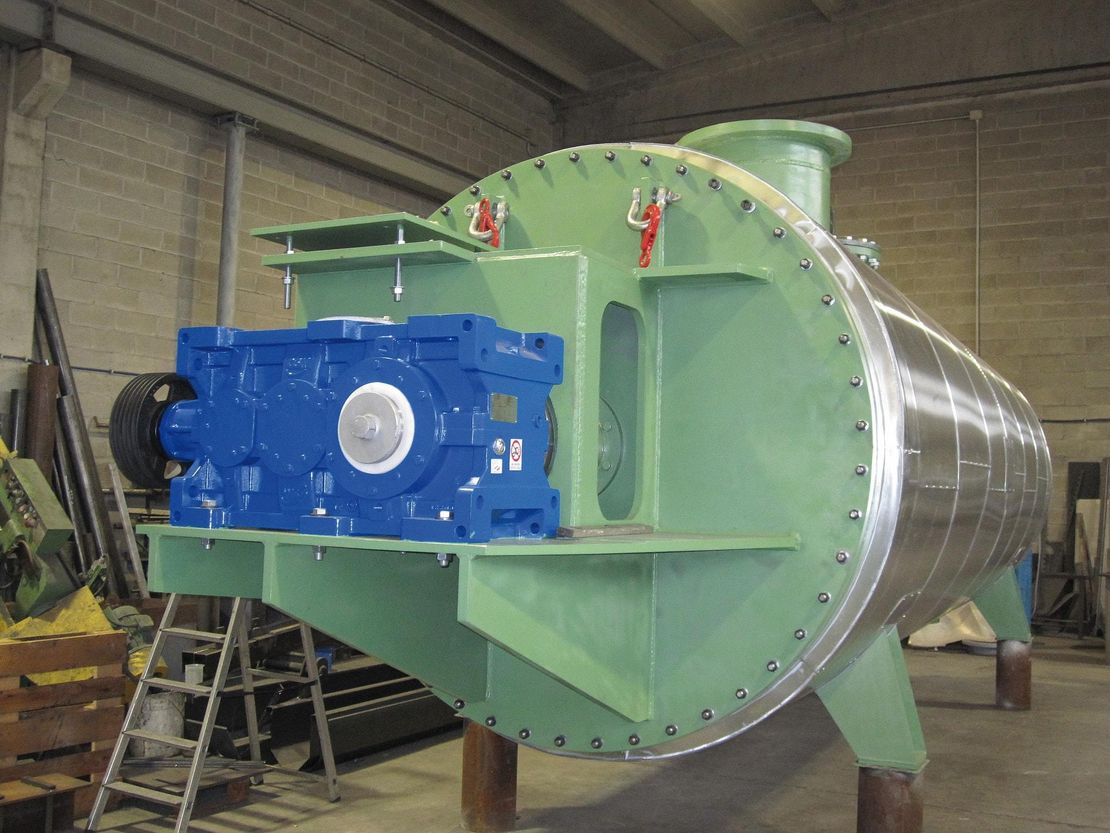

BATCH COOKER

P.C.M Srl, as a rendering plant manufacturer, supplies a wide range of certified pressure batch autoclaves, to reach the production performances requested by the animal rendering companies.

The disposal of the poultry and red meat by products produced from abattoirs, forced P.C.M Srl to realize a high-tech cooker.

Autoclave is the most important rendering equipment and primary component of every plant for production of animal meal: this batch cooking system is able to perform the hydrolysis process of the feathers mixed with blood and poultry offal, and transform them in a meal having few field of application.

The CBD discontinuous cooker by P.C.M Srl is composed of a cylindrical casing with horizontal axis, made of strong thickness carbon steel sheet, with a steam circulation heating jacket.

The agitator is composed of a tubular axis with end parts in high-strength forged steel, with tubular arms carrying special mixing blades.

A special rotary joint is located at the front end of the shaft for steam injection and condensate drainage.

The autoclave is complete of two pneumatic guillotine valves for material’s loading/unloading.

The cooker is pre-assembled on a steel basement and insulated with rock wool covered of aluminum sheet.